2022-09-20

With the rapid development of modern industry, the food industry has also enhance requirements for packaging accuracy, packaging speed and application. At present, traditional quantitative automatic weighing scales have been difficult to meet these requirements. In contrast, the weighing accuracy of multihead weigher is much higher, which gradually replaces traditional packaging scales and become more demanded product.

So compared with traditional quantitative weighing scales, why multihead weigher precision is higher?

1. Different weighing principles

The traditional quantitative automatic weighing scales is weighing while feeding, and continues to feed until the target weight data is reached. When the target weight is slightly different, a weighing object must be added. It mean the rough weighing is followed by the precision weighing, such as being weighed. When the object is large or heavier, there will be a large error, which affects the accuracy of its weighing.

The computer multihead weigher is composed of multiple weighing units with independent feeding and discharging structures. Generally, it is composed of 8 to 32 weighing units. When the weigher is working, the computer uses the principle of permutation and combination to automatically optimize and calculate the load of each weighing unit, and obtain a combination that is close to the quantitative value for packaging.

For example, a computerized combination weigher with ten weighing units, each weighing unit is weighed, and the data of each weighing hopper is read into the computer, and the computer makes an optimal combination and selects a combination that is close to the target weight value.

In this way, Precise weighing can be used to solve the problem that the single weight of the weighed object is large and the quantitative value is difficult to achieve. The computer multihead weigher uses a combination close to the target weight as the final result.

2. Different weighing speed

Traditional quantitative automatic weighing scales generally(usually) have(need) to go through rough weighing and precision weighing process, especially the process of precision weighing process needs to be added bit by bit, which takes a long time and affects the weighing speed, which is generally 20 to 30 packs / min, and In optimal combination calculation system of multihead weigher, 14 head load cells speed can reach 100-120 wpm, The weighing speed is 4-6 times faster than the quantitative automatic weighing scales, and it is easy to cooperate with various packaging machines, which greatly improves the production efficiency and is more suitable for the needs of modern production management.

3. Different weighing range

In the case of the same accuracy, the weighing range of the computerized multihead weigher is larger than that of the quantitative automatic weighing scales. Generally, The weighing range of quantitative weighing scale is within 4 times under the same accuracy, computer multihead weigher in the small weighing section can reach more than ten times.

If you want to maintain the accuracy level, the quantitative automatic weighing scales can only reduce the weighing range to make it multi-stage weighing. The only one solution is to produce more machines of the same series, which greatly increases the production cost, and brings its limitations Fail to meet the requirements of different packaging range (10-1000g) with similar accuracy in some industries.

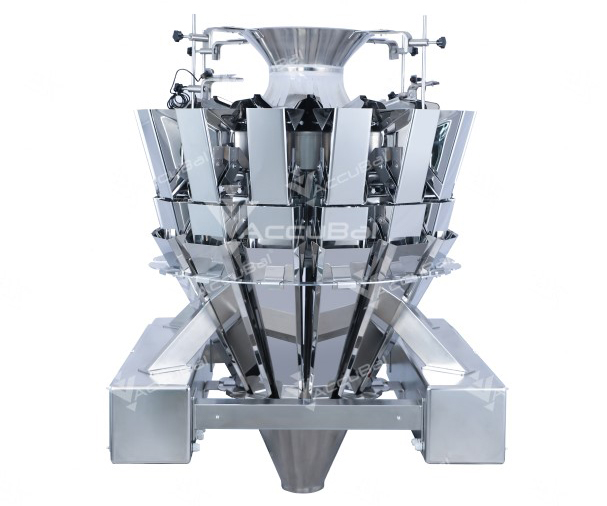

Accubal High-end 14-head Model

As an internationally renowned manufacturer of automated weighing and measuring equipment, Accubal developed a variety of multi-head microcomputer multihead weighers with international standards, which can achieve all tasks such as measuring, feeding, filling, bag making, and date printing in the fully automatic packaging process., Integrating accurate weighing, fast packaging and weight detection, in addition to the automatic statistics function of large-volume data, it can also accurately count the total number of products, the qualified rate, the average error of a single bag, etc., completely solved the packaging problem of domestic and foreign food production manufacturers.

AccuBal has won more than 40 patents at home and abroad. Our AB-2C waterproof 10-head and 14-head microcomputer multihead weigher is popular in domestic and foreign market!

Accubal, with its international management model, innovative business philosophy, and strong operating strength, can provide customers with integrated solutions from product design and development, manufacturing, marketing, installation and commissioning, technical training to after-sales. Welcome to consult!

Phone: +86 180 2276 8015

E-mail: export@abscale.net

Add.: No.31 East Shunye Road, Xingtan Town, Shunde District, Foshan City, P.R. China

Follow Us